Overview

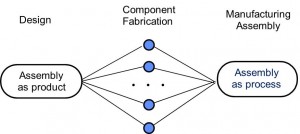

Assembly is the beginning and end of production realization. Product development begins with the design of product as an assembly. Questions about design for manufacturing and design for assembly are usually asked and answered during this time. Product realization ends with “assembly” as the capstone process where components and subsystems come together to form the final assembly. The assembly systems play a critical role in product quality, system productivity and cost. To quote Dan Whitney, “Logistical issues, supply chain management, product architecture, mass customization, management of variety and product family strategies … are enabled during assembly design and are implemented on the assembly floor”.

Our research in this area includes projects in “Assembly in the Large” and “Assembly in the Small”. “Assembly in the Large” views assembly at the systems level, such as assembly decompositions and supply chain configuration, modeling of variation propagation in multi-stage systems. “Assembly in the Small” views assembly at the processes level: such as modeling the contact resistance in fuel cell assembly.

Current Projects

- Integrated Assembly Decomposition and Supply Chain Configuration

- Assembly System Configurator for Lithium-Ion Battery Manufacturing

- Modeling Product Variety Induced Manufacturing Complexity for Assembly System Design

Past Projects

- Complexity Analysis of Assembly Supply Chains

- Dimensional Variation Analysis for Light Weight Structures

- Adaptive Control of Assembly Quality using Programmable Tooling

- Assembly and Performance Modeling of PEM Fuel Cells

- Contact Resistance in ACA