Modeling Product Variety Induced Manufacturing Complexity for Assembly System Design

Background

- Product variety induced manufacturing complexity is a critical problem faced by all manufacturers in today’s competitive environment as manufacturers are developing customized products to respond to individual needs.

- As such, the proposed research will have broad potential benefits in that the developed models, algorithms, and guidelines will be able to assist manufacturing system designers in managing complexity when designing manufacturing systems, which will result in improved operator and system performance.

Objective

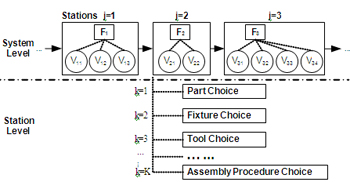

- To develop mathematical models on product variety induced manufacturing complexity in multi-stage, mixed model assembly systems

- To gain insights on the impact of such complexity on system performance

Approach

- Multi-stage models will be developed to characterize the propagation of complexity by considering the choice complexity induced at each station and the transferred complexity from the up-stream stations.

- Bayesian network (BN) models will be developed to quantify the impact of the complexity on the system performance, including quality and operator productivity.

- When validated, the developed complexity models will be applied to improve assembly system design and synthesize guidelines for managing complexity in manufacturing system development.

Researcher