Integrated Assembly Decomposition and Supply Chain Configuration

Background

- Separate, uncoordinated approaches to module generation and supply chain planning have prevented optimal concurrent module re-configuration and supplier selection, and have led to unnecessary cost increase and delayed product validation.

- Product module design and supplier selection for the modules have traditionally been carried out independently even though they are highly interwoven activities.

Objective

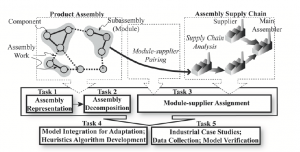

- To develop a novel module-centric integrated adaptation approach through which product design, assembly manufacturing and supply chain decisions are made in a cohesive fashion centered on assembly modules.

Approach

- Development of a hybrid graph-theoretic assembly representation considering assembly processes

- Development of mathematical methods for assembly decomposition and subassembly validation

- Establishment of module-supplier assignment models considering supply chain performance

- Model integration and development of an efficient heuristic algorithm

- Industrial case studies and methodology verification

Researchers