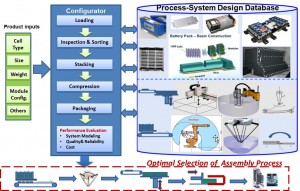

Assembly System Configurator for Lithium-Ion Battery Manufacturing

Background

- Lithium-Ion battery technologies are changing rapidly as new cell chemistry and cell types are being developed.

- Demand for lithium-Ion batteries is highly variable since the electrical vehicle market is still developing.

- The assembly systems for battery packs much be reconfigurable.

Objective

- To develop the mathematical tools and software system which serve as a battery assembly system “design aid”.

- Given cell types and geometry and the pack volume demand, generate assembly system configurations

- Perform throughput analysis and cost modeling to select best configuration

Approach

- Develop a system design database of stacking machines

- Create algorithms to generate automated assembly system alternatives

- Output such configurations to Witness for performance evaluation

Researchers

- Lisa Li

- Henry Kuang

- Hui Wang

- Sam Yang