Complexity Analysis of Assembly Supply Chains

Background

- Product variety increases due to today’s fierce competition in market

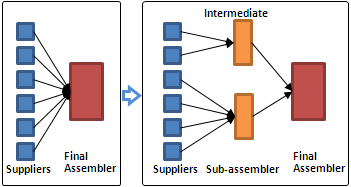

- Companies move from traditional non-modular assembly supply chains to modular assembly supply chains to cope with the increasing variety

- Companies want to know how to make the decisions about supply chain configuration

- Direct cost comparison is difficult and some parameters are not available

Objective

- Proposing to use a new performance measure, complexity, to evaluate the supply chain

- Investigating the relationship between complexity and cost of an assembly supply chain

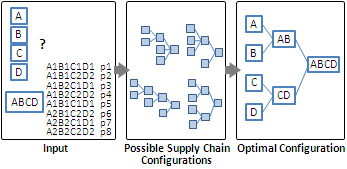

- Developing an algorithm to find optimal supply chain configuration

Approach

- Defining the complexity measure based on Shannon’s information entropy

- Using majorization theory and Design of Experiments (DOE) methods to study the relationship between complexity and cost

- Developing an iteration decomposition algorithm to find optimal supply chain configuration

Researchers

- Hui John Wang

- Prof. Goker Aydin (IOE)