Throughput Analysis of Manufacturing Systems with Closed Loop Material Handling Systems

Background

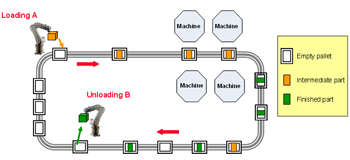

- Closed Loop Material Handling Systems (CL-MHS) are widely used in various manufacturing environments to save space or reduce overall cost.

- Many system parameters of such CL-MHS need to be setup or adjusted such as the right pallet number, conveyor index speed, the loading and unloading positions, etc. Currently the only available means of determining such important parameters is based on simulation, which is very time consuming, inconsistent and ad hoc.

Objective

- To develop mathematic models and algorithms on quick analysis and optimization of Closed Loop Material Handling Systems (CL-MHS) in various manufacturing environments

- To implement such closed loop MHS analysis module into PAMS software and validate its effectiveness in practice

Approach

- The workload balancing principles

- A set of dynamic system analysis methods based on parameter coupling and feedback mechanism

- The algorithms have been successfully implemented in PAMS 5.0.

Researcher