Monitoring of Body Shop Welding/Joining

Background

- GMAW (Gas Metal Arc Welding) is widely used as a important joining process in automobile fabrication line.

- However, GMAW is prone to various weld discrepancies, resulting in high scrap rate and rework.

- Therefore, the monitoring system is needed to improve weld quality and to reduce manufacturing cost.

Objective

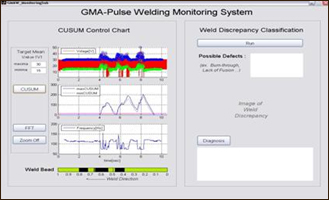

- To develop a network based weld quality monitoring system to automatically detect and classify weld discrepancies.

Approach

- Measurement of electric signals (voltage, current) during welding

- Signal processing of electric signals

- Detection of transfer mode changes

- Detection of weld discrepancies using STFT and CUSUM control chart

- Visualization of weld bead

- Programming of Graphic User Interface

Researcher