Curing induced distortion in adhesive bonding of dissimilar materials

Background

- To reduce vehicle structure weight, lightweight materials (aluminum, composite, high strength steel) are used in autobody manufacturing, which pose a challenge for joining.

- Adhesive bonding offers advantages for joining similar and dissimilar materials.

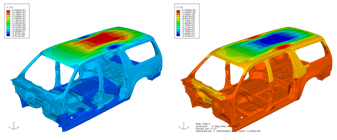

- Severe curing induced distortion is observed for aluminum roof-to-steel body side assembly in Fuel Efficiency Learning Vehicle (FELV).

- Little information is available concerning curing induced distortion using crash-toughened adhesive. Tool or methodology is needed for body design to minimize bonding induced distortion.

Objective

- Develop predictive capability to analyze dimensional variation of adhesive bonded joint

- Establish design and manufacturing guidelines for adhesive bonding of body structures

Approach

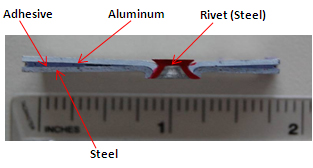

- Modeling of rivet-bond joint

- Modeling adhesive cure processes, including heating, curing and cooling

- Coupon-level modeling and experimental verification of dissimilar materials

- Structural modeling: aluminum roof-to-steel body assembly of FELV and NG_Delta

- Methods to reduce curing-induced distortion

Researchers

- Liang Zhou

- Baiyan (Brian) He